Perfection from design to completion

Sheldon Industries has broad experience and plenty of prestigious references in the automation and the robotics sector. We aim to bring Industry 4.0 manufacturing technologies into our costumers’ everyday life. All the equipments and machineries are built and designed in-house. We also program the PLC and other process controlling devices.

We offer all-inclusive solutions from initial design to the „ready to use” product with follow up services.

creativity & knowledge

our company

Industry 4.0 and automation

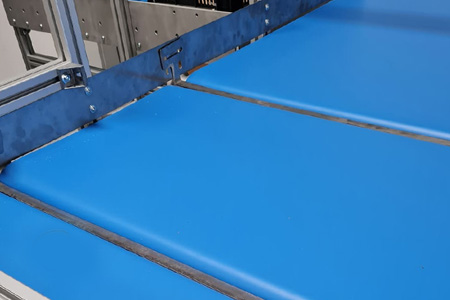

Regarding its core business, our company deals with the design, development and construction of industrial automation, including robot cells, assembly and production lines, and special purpose machines. These special-purpose machines are intended to replace and automate human workforce during certain manufacturing processes. We mainly manufacture such systems, designed for individual needs, primarily for the food industry, mechanical industry and automotive companies.

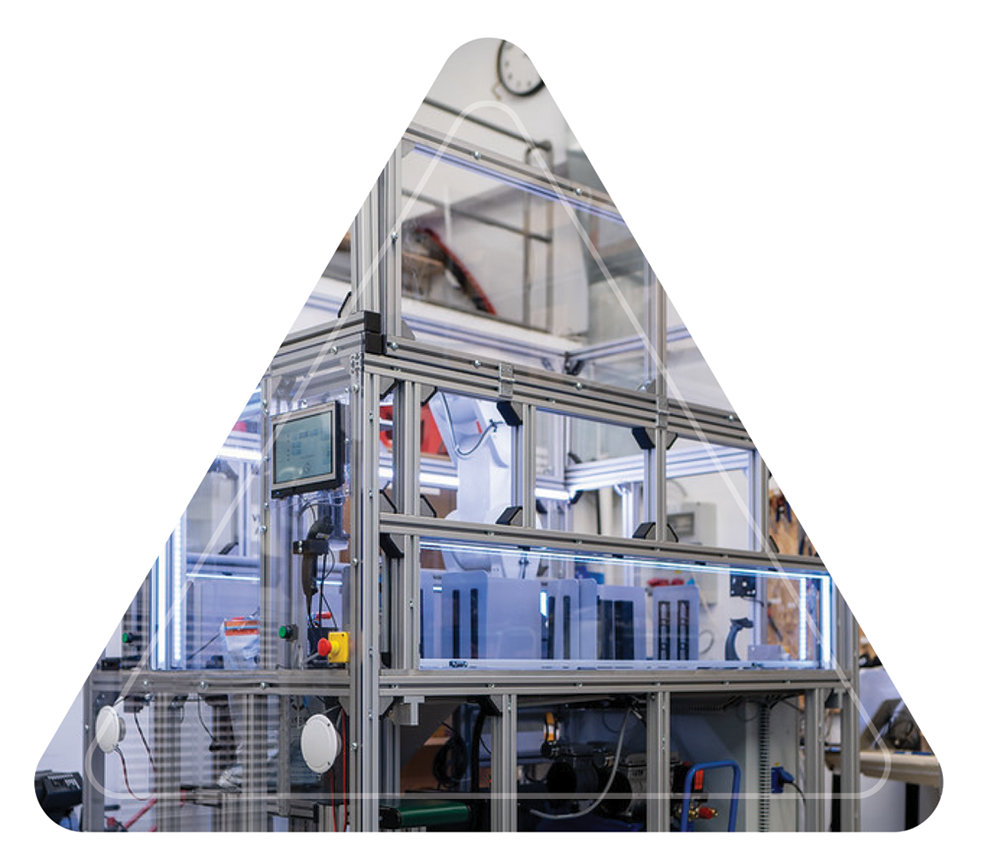

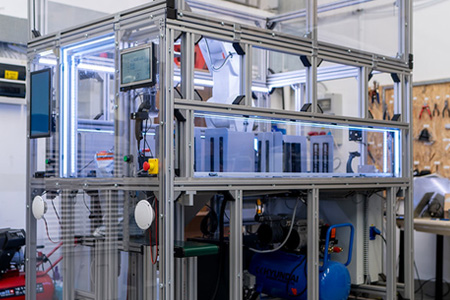

"Ready-to-use" construction

We offer complete solutions from idea to the „ready-to-use” products. The machines and systems we design meet the requirements of the Industry 4.0. The smart manufacturing process (with SCADA system) enables constant online connection even remotely for modern production processes with the aim of ensuring that production is networked in the best possible way. As a result, production should control itself as far as possible and optimize itself.

Competitive advantage with knowledge and experience

One of our biggest competitive advantage is that we are experts in building machines with stable, reliable, and efficient mechanics. This part of the manufacturing process requires one of the most difficult and demanding tasks and „know-how”. We have the necessary experience and knowledge.

Visualization each phase of a product's journey

What really makes us unique is that we implement the Iconics Manifacturing Execution System that manages and monitors work in progress on the factory floor. This system relies on up-to-date info to provide a snapshot of the current state of products being manufactured. It can visualise and control processes from dashboards and able to analyse workflow at every step.

solution for the future: automation of the whole production process

Activities

Sheldon specialises in industrial automation; designing, developing, building and commissioning robot cells, assembly lines, manufacturing lines and customized machines.

Factory solutions for:

▲ Exchanging manpower to production lines

▲ Robotisation of complex and heavy work

▲ Automation of high repetition, precise work

Our company primarily provides industrial automation solutions in the following sectors:

automotive industry

food industry

packaging technology

agricultural automation

machine manufacturing

light industry

APPLIED TECHNOLOGIES

▲ From design to programming

Our team of highly skilled engineers use the latest SolidWorks® software for product design. We are able set up SCADA systems to control industrial processes and we use Mitsubishi’s PLC controlled robots as well.

▲ Composite 3D printers

The 3D printed parts are durable and strong – up to aluminum strength – using carbon fibre, Kevlar® fibre and continuous fibreglass materials.

▲ 3D metal printing

On-demand custom 3D metal printing services for prototyping and production metal parts and tools. Materials used by the Metal Desktop Studio System 2 printers: stainless steel, tool steel, heat resistant steel.

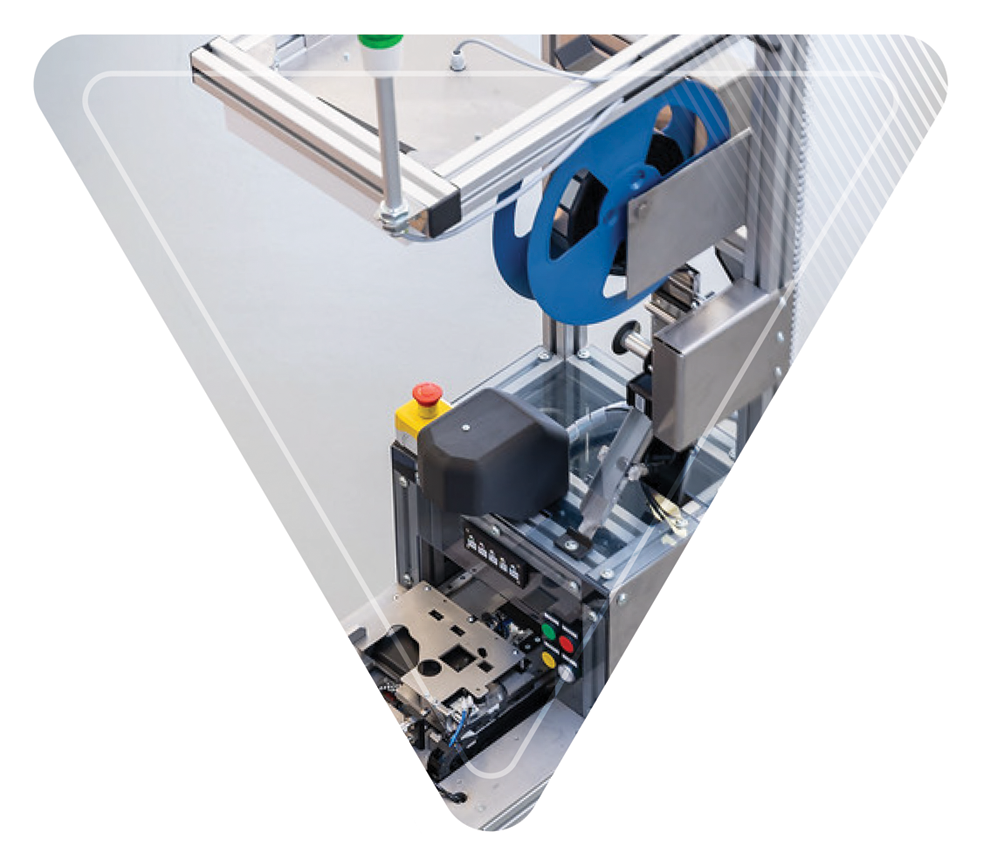

▲ Metalworking

The high-quality components are manufactured by CNC, water jet cutting machine, wire cut EDM and a range of common metalworking machines.

MAIN AREAS OF PROCEDURES

Assembly equipment or measuring instruments with moderate automation

Closed interconnected, trackable assembly stations

Unique, separate manufacturing equipment with special functions

Automatic robot cells

Manufacturing- and assembly lines

Production line equipment with monitoring and visualization system

ReferencES

We handle the process from a single design and 3D printing assignment to large scale production line building and commissioning. A few examples of our more sophisticated solutions:

▲ In the food industry: modern packaging of products from assembling to loading the boxes.

▲ Safe working environment accomplishment by automated sawing cells

▲ Automatic transmission assembly

▲ 800 pieces per minute dairy industry product packaging

▲ Smart system for filling ice cream

▲ Quick, low cost and efficient labelling

▲ Potato selecting machine automation

Contact

view map

zoltan.rigo@sheldon.industries

+36 20 667 3387

1221 Budapest, Orsovai u. 3.

Factory: 2400 Dunaújváros, Táncsics Mihály u. 1/a

(University of Dunaújváros, Building GL)